Valves

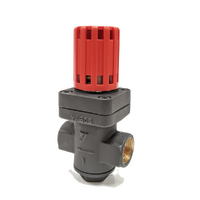

PCI has a full range of valves based in Geelong for industrial applications. This includes Ball Valves, Butterfly Valves, Check Valves, Gate Valves, Globe Valves, Pressure Reducing Valves, Pressure Relief Valves and Solenoid Valves. We also have access to all leading valve manufacturers internationally if you need us to source a particular brand. Having this valve range in Geelong we can achieve same day delivery into Melbourne and surrounding suburbs.

Subcategories

-

What are control valves used for?

Control valves are mechanical devices used to regulate the flow, pressure, and temperature of gases and liquids through a pipeline or process system. They consist of a valve body, an actuator, and a control mechanism that adjusts the position of the valve plug or disc in response to a signal from a controller. Control valves are used in a wide range of applications, including oil and gas production, chemical processing, power generation, water treatment, and HVAC systems. They can be operated manually or automatically, and are equipped with sensors, actuators, and controllers that allow for precise adjustments to the valve's position and flow rate. The valve's performance is crucial to maintaining the efficiency and safety of the process system. Therefore, they are designed to withstand harsh operating conditions, and their accuracy and reliability are critical to the smooth operation of the process. -

How control valves work

The valve body of a control valve is connected to a controller, which monitors the process variables, such as pressure, temperature, or flow rate. Based on the input from the controller, the valve's actuator adjusts the valve's opening, allowing more or less fluid to flow through the passage. This adjustment can be made either manually or automatically, depending on the type of valve and the application. Control valves can also be equipped with various accessories, such as positioners, which ensure accurate valve positioning, or limit switches, which provide feedback on the valve's position. These accessories enhance the valve's performance and allow for greater precision and control over the process variables. -

Types of control valves

There are several types of control valves, each with their own unique features and applications:Pressure reducing valves: These valves reduce fluid pressure in a pipeline or system, and are often used to protect downstream equipment.Globe valves: Named after their spherical shape, these valves have a linear motion in which the valve stem moves up and down to control flow rate. They are commonly used in applications that require precise control.Gate valves: Designed to either fully open or close, with a disk that moves perpendicular to the flow direction, gate valves are commonly used in applications that require on/off control.Butterfly valves: Using a circular disk with a pivot in the center to control flow, these valves are commonly used in applications that require quick opening or closing (majority are on/off applications)Ball valves: These valves use a sphere-shaped ball with a central hole to control flow. They are commonly used in applications that require high flow rates and on/off control.Solenoid valves: Using an electric coil to actuate the valve, solenoid valves allow for remote control. They are commonly used in applications that require quick response times.Check valves: Check valves allow fluid to flow in one direction, preventing backflow. They are commonly used in applications that require protection against contamination.Pressure relief valves: Pressure relief valves are designed to relieve excess pressure in a pipeline or system, protecting against damage or failure. -

Valves used across different industries

Valves are used across many different industries - oil and gas, power generation, water treatment, and HVAC, to name a few. For example, chemical plants use valves to control the flow of hazardous chemicals and ensure the safe operation of various processes. In the pharmaceutical industry, valves are used in sterile processing systems to maintain the purity of different products. Valves are also used in the food processing industry to control the flow of liquids and gases, as well as to prevent contamination. The type of valve/s used depends on the specific application requirements, such as flow rate, pressure, and the type of fluid or gas being controlled.